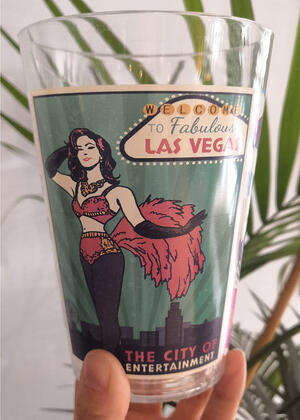

As we move into a new decade, consumer inclination for personalized and customized packaging continues apace, prompting the need for shorter runs, quicker turnaround times, and the flexibility to utilize variable data to produce individual designs. The food and beverage market is leading the way, as evidenced at PRINTING United 2019, during which exhibitors showcased digital direct-to-shape solutions with a focus on drinkware applications.

As we move into a new decade, consumer inclination for personalized and customized packaging continues apace, prompting the need for shorter runs, quicker turnaround times, and the flexibility to utilize variable data to produce individual designs. The food and beverage market is leading the way, as evidenced at PRINTING United 2019, during which exhibitors showcased digital direct-to-shape solutions with a focus on drinkware applications.

Engineered Printing Solutions displayed the MD-9450 cylindrical inkjet printer through a partnership with Machines Dubuit, Inkcups introduced its new Revolution digital cylinder printer as well as its Helix and X360 models, and Marabu North America demonstrated its first digital printer, the M Revo.

While the customization trend will continue to drive direct-to-shape inkjet growth, the technology is not without its challenges. While many of the individual components are viable, a lack of manufacturer collaboration as well as paucity of R&D funding means widespread adoption is still a way off. While "out-of-the-box" solutions are available, often a bespoke system is required, with systems integrators designing tailor-made direct-to-shape units based on a client’s unique requirements.

The modular nature of direct-to-shape inkjet systems has prompted brands to bring packaging printing in-house, allowing them to easily modify packaging designs, manage lead times, and customize packaging to accommodate initiatives such as special promotions, seasonal or localized changes, and personalizing packaging to consumers. While the efficiency of direct-to-shape inkjet has some way to go, for these smaller operations, the benefits of autonomy over the package printing process far outweigh slower speeds.

The modular nature of direct-to-shape inkjet systems has prompted brands to bring packaging printing in-house, allowing them to easily modify packaging designs, manage lead times, and customize packaging to accommodate initiatives such as special promotions, seasonal or localized changes, and personalizing packaging to consumers. While the efficiency of direct-to-shape inkjet has some way to go, for these smaller operations, the benefits of autonomy over the package printing process far outweigh slower speeds.

When it comes to many leading packaging trends, direct-to-shape inkjet technology has the ability to meet many of the key requirements, and thus will become a desirable replacement technology for label printing in certain areas. However, it’s not something that will happen overnight. As key challenges are overcome and knowledge and awareness of the applications advance, we will see the technology become a more mainstream player in the customized and personalized packaging space.