As 3D printing technology advances, and becomes more accessible, the opportunities in this market continue to grow. The Alliance asked Josh Hope, senior manager, Digital Imaging & Innovation, Mimaki USA, for insights on the latest developments and the trends he's observing.

How has 3D printing technology advanced in the past five years?

3D printing and additive manufacturing in general have been growing exponentially in the last five years. We have seen so many new technologies entering the market and many more refinements on existing technologies and materials. From polymer to metal printing, the advancements are astounding.

How has the 3D printing market been impacted by the pandemic? What about supply chain issues?

The pandemic was a very interesting time to see how manufacturers and companies were able to pivot from a profit-centric mindset to seeing how existing equipment and resources could be used to help provide support for people trying to weather these challenging times. From facemask strap relief to face shield frames and touchless door handles, there was an amazing outpouring of both time and materials from many companies looking to help anyone who needed it.

What are the trends you’re seeing in terms of 3D printing applications? Where do you see it expanding opportunities for print service providers (PSPs) in the future?

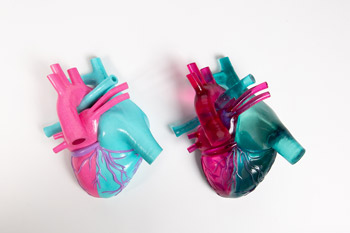

The lesson in looking at trends in 3D printing applications is to really open your mind and not be limited by any preconceived notions of what additive manufacturing processes can do. From point-of-purchase displays to flatbed printing jigs, to specialized tools, to personalized collectables, there is really no limit to the opportunities. The technology is more accessible today than ever with so many online resources — it is an excellent time to get started with 3D printing.

What are major considerations for PSPs looking into 3D printing in terms of the process (design, production, finishing, etc.), and adding the technology to their operations?

As with any technology acquisition, define the market you want to address and find your customers. There are existing 3D service bureaus now that can help with printing initial samples for customer meetings and can provide short-run printing as PSPs ramp up into production. Our advice is to match the technology of the intended purchase with the needs of the PSP’s customer base.

The great thing is that the general 3D skills learned on even very basic 3D printers translate to the larger production printers as production increases. Designing for 3D can be complicated but depending on the technology, printing and finishing are well withing the grasp of most PSPs. When looking at 3D printing equipment, PSPs should be sure to get an understanding of the finishing processes and equipment that may be needed. Typically, there is some sanding or polishing that will need to be done. Often it can be done manually, but as production demand increases, you will want to be able to automate those processes as much as possible.

*Images courtesy of Mimaki.