With its variety of applications — from rigid substrates to fabrics — dye sublimation printing is a growing industry trend. However, like any printing method, it has its own considerations, technology and processes — all of which require a thorough understanding and proper training.

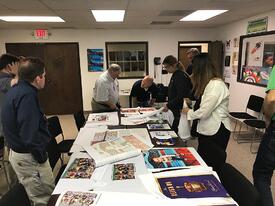

With its variety of applications — from rigid substrates to fabrics — dye sublimation printing is a growing industry trend. However, like any printing method, it has its own considerations, technology and processes — all of which require a thorough understanding and proper training. SGIA’s upcoming workshop, Sublimation 101 for Wide Format Graphics (June 18 - 19; Rolling Meadows, Ill.), is designed to provide essential hands-on education for producing banners, soft signage and interior applications. Hosted by IT Supplies, the workshop features a smaller-class setting conducive for one-on-one training, enabling attendees to practice on dye sublimation equipment and enhance their skill sets.

I spoke with instructor Ray Weiss, SGIA’s Director of Digital Print Programs, on why printers are opting to use dye sublimation and what attendees can expect to gain from this in-depth training, whether they are a new printer or looking to integrate this production into their business.

Searson: Why is dye sublimation printing a growing trend for wide-format graphics?

Weiss: Typically dye sublimation is used more now in trade-show graphics because the “look” of the graphics are not as harsh as the old film type of substrates. Another benefit of dye sub is having “lighter” graphics for shipping which are less likely to “crease,” which can make a graphic unusable.

What are significant considerations for printers starting a business or seeking to add dye sublimation printing to their production?

There are many more variables to take into consideration when going into dye sub printing as an existing printer, and it’s a ton of information to learn as a new person getting into this business.

There are many more variables to take into consideration when going into dye sub printing as an existing printer, and it’s a ton of information to learn as a new person getting into this business. For example, dye sub adds the variable of heat to the printing process — which can add stretch to many fabrics and definitely impacts print quality. We’ll be discussing flatbed and rotary heat presses, fabric options, transfer papers, dye sub ink technologies and more.

What additional information does this workshop address for attendees?

In addition to attendees learning about the processes, we demonstrate color management in the dye sub arena. This includes device calibration, and navigating an RIP workflow with spectrophotometers.

What tends to be the biggest challenges when it comes to color control in wide-format dye sub printing? How will this training address those?

The biggest challenge is all the variables that need to be controlled. As this training talks about all the different components — papers, fabrics, heat presses, printers, inks, etc. — we bring in experts in all these areas to address them, and the students learn how to manage those variables.

The biggest challenge is all the variables that need to be controlled. As this training talks about all the different components — papers, fabrics, heat presses, printers, inks, etc. — we bring in experts in all these areas to address them, and the students learn how to manage those variables. Everything we cover in this workshop comes down to helping businesses increase their profitability. We want attendees to be aware of where they can avoid costly mistakes in the overall process.

Join Weiss and other industry experts for Sublimation 101 for Wide Format Graphics. Register today.